– Modbus TCP Server/Client connections on external Ethernet port – All basic I/O modules, both analog and digital – P1000 CPU’s and local I/O stack, P2000 and P3000 CPU’s and local bases

#Free plc software simulator series

P1000, P2000, and P3000 emulation can happen on the following parts of the productivity series hardware: The entire family of controllers can use the simulator. This software will now allow you to test or troubleshoot your program without the physical hardware present. The software is a free download and is available from automation direct. The productivity suite software now contains a plc simulator.

#Free plc software simulator simulator

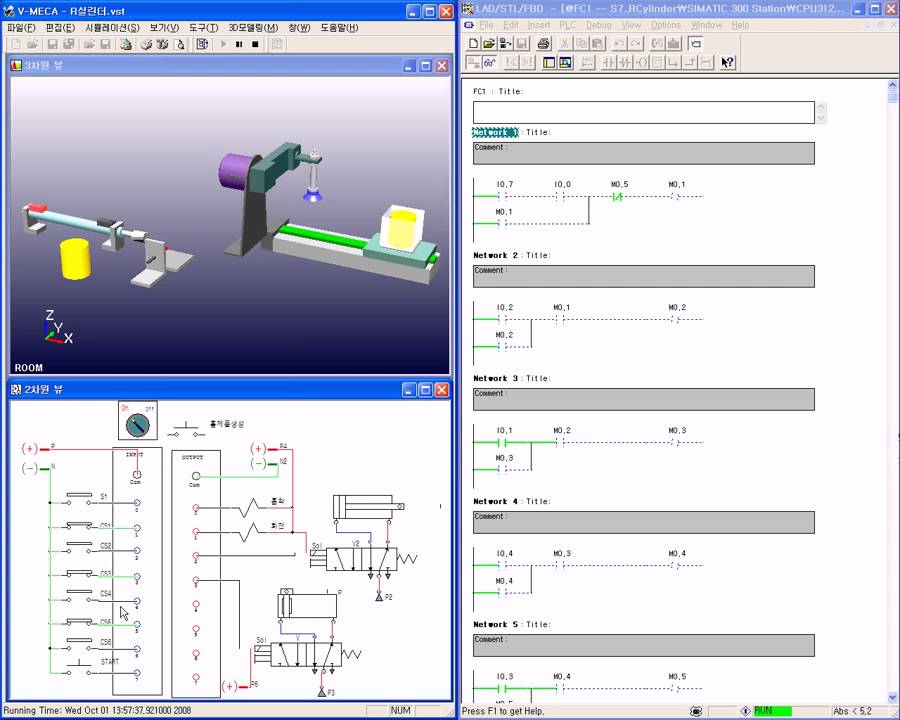

Keep on Reading! #machinesimulator acc automation automation Automation Direct automation direct plc automationdirect chain chain conveyor Conveyor conveyor system easyplc easyplc chain conveyor easyplc machine simulator engineering free plc simulator low-cost plc machine simulator PLC plc programming plc simulator productivity 1000 series productivity plc productivity plc simulator productivity plc simulator - chain conveyor ms productivity plc training tag based plc Using the five steps for program development we will show how this is programmed. This will be done using Modbus TCP (Ethernet) for communications. Using the Productivity Suite software, we will connect the simulator to the chain conveyor transfer machine. The productivity series of PLCs will be used to program this virtual machine. It will transfer large and small boxes on the line to different locations. The chain conveyor is one of these machines. It has many built-in machines that can be programmed. The Machine Simulator (MS) is part of the EasyPLC software suite.

0 kommentar(er)

0 kommentar(er)